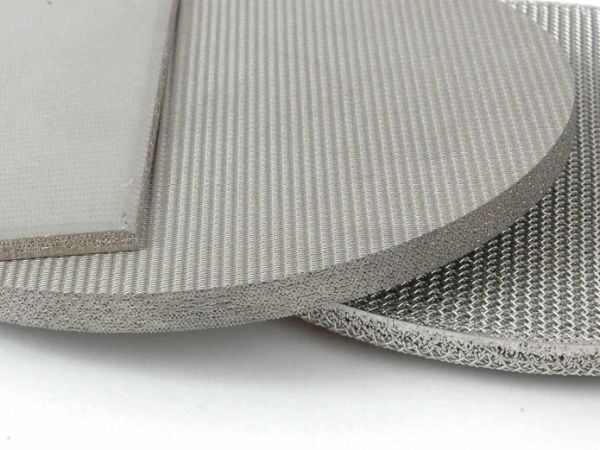

We are committed to crafting high-quality, reliable products

We were founded in 2010 and are one of the earliest enterprises in China to produce stainless steel mesh. The company focuses on the production and research and development of stainless steel mesh products, with the most advanced production technology and equipment, as well as a professional sales team.

20+ countries

2010+ founded in

8+ sectors

We are committed to providing customers with comprehensive and efficient service solutions, tailor-made for you.

Jan 23, 2026 – The global wedge wire screen market is poised for steady growth over the next decade, fueled by rising investments in infrastructure upgrades, stringent water treatment regulations, and expanding mining activities worldwide. According to a recent report by Report Prime, the market, which was valued at $1.22 billion in 2024, is projected […]

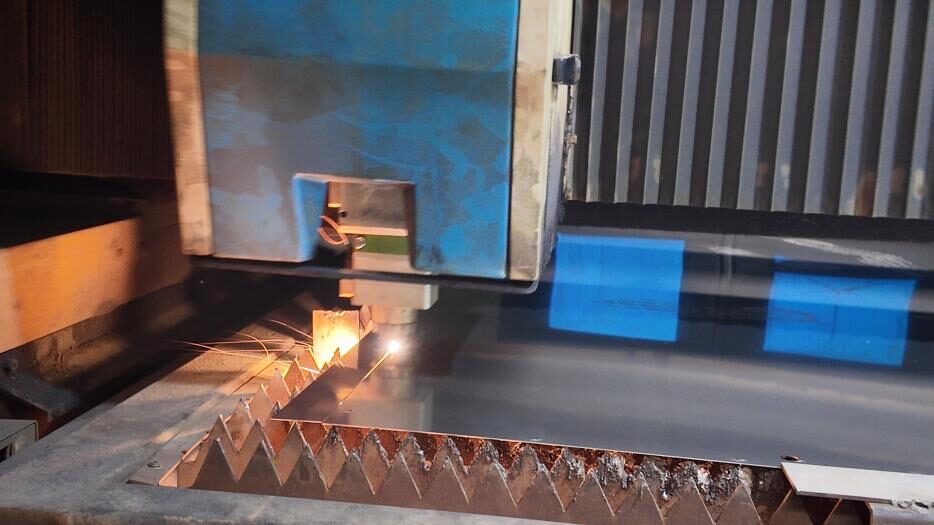

Jan 22, 2026 – The Johnson screen cylinder industry is witnessing a wave of technological innovations, with laser welding precision and deep customization capabilities reshaping product performance and application scope. Manufacturers are increasingly focusing on advanced processes to meet the complex requirements of extreme working conditions, such as high corrosion, high wear, and non-standard installation […]

Jan 21, 2026 – The Asia-Pacific region has solidified its position as the global center for Johnson screen cylinder production and consumption, with Chinese manufacturers leading the charge in technological innovation and global market penetration. Leveraging complete industrial chains, cost advantages, and advanced manufacturing capabilities, regional players are challenging established Western brands and expanding their […]

Copyright © 2025 Anping County Chuangtuo Wire Mesh Products Co., Ltd All Rights Reserved.